What is a P5 and P10 display panel?

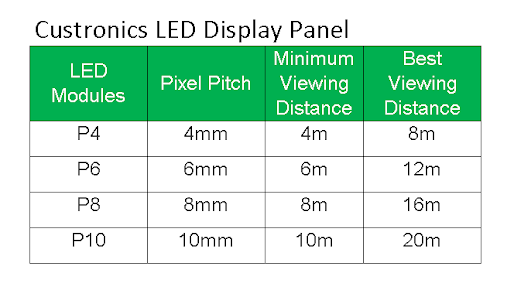

P is basically stands for pixel spacing, and the numbers stands for the spacing in between each of the LED. Example, each of the LED gap in between for P6 display panel is 6mm, and for the P10 display panel is 10mm.

What is a pixel pitch?

Pixel pitch refers to the density of pixels. Pixel pitch is important because it influences the viewing distance. A smaller pixel pitch indicates higher pixel density and higher resolution. So, the viewing distance will be closer.

A P5 usually comes with 64 pixels across and 32 pixels down, whereas a P10 usually comes with 32 pixels across and 16 pixels down. In this case, P5 has higher density compares to P10.

What is difference of DIP SMD P10 P6 RGB & Single Colour LED module? how to we differentiate LED Display module indoor / outdoor? What type of controller & interface that we have. I hope you found this informative! I would love to hear your thoughts – so please comment below if you have any question. #p10led #p10ledboard #ledscreen #custronics #jttechtronicssdnbhd #andondisplay #leddisplaypanel #leddisplaymalaysia #ledboard #electronicsdisplay #andonsystem #ledsystem

LED Display System Design & manufacturer

CUSTRONICS

Engineered & Assembly in Malaysia

https://www.facebook.com/JTTechtronics/

https://www.custronics.com

CUSTRONICS

Engineered & Assembly in Malaysia

https://www.facebook.com/JTTechtronics/

https://www.custronics.com

Jim Loo

https://Www.wasap.my/60163199391 #custronics #jttechtronicssdnbhd #PPMdisplaypanel #MPMDisplaypanel #KPIdisplaypanel #productiondisplaypanel #leddisplaypanel #malaysialed #leddisplaypanelmalaysia #leddisplaymalaysia #leddisplayboardmalaysia #leddisplayboard #productiondisplayboard #productiondisplaymalaysia #rs232display #rs485display #mqttdisplay #andonsystem #andondisplay #andonleddisplay

For DIP that every pixel is made of three free color(RGB) LED bulbs. Every bulb have two long feet. The long feet are embedded into PCB cushion, so later through-opening fastening that there will be rarely cool welding issue. The SMD LED show has short feet and the drove light was mounted on the PCB cushion which is more straightforward to cause cold welding issue than the DIP one

ReplyDeleteIt was so beautiful. I really can't say anything. Thanks for the nice article.

indoor SMD display